GenreEnterprise TrainingPlatformQuest 2RoleLead, Networking, AnalyticsYear2022Duration6 months

About

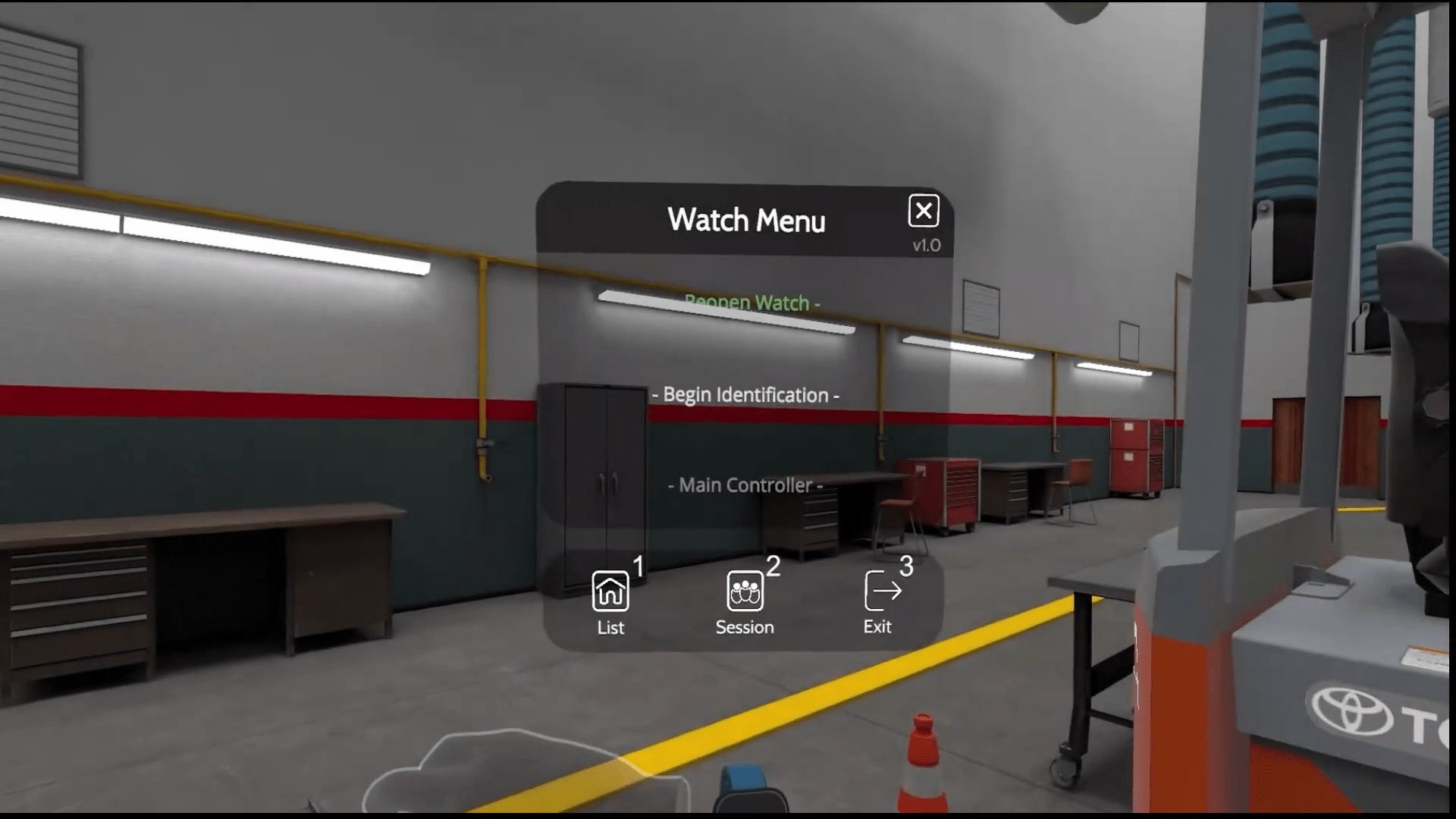

A virtual classroom for teaching component identification on Toyota electric forklift models. The user is able to select single player courses with narrations, or join a live class hosted by an instructor. The course covers the initial PPEs, removing the external covers, and identifying components. There’s a final evaluation course where the user performs the steps without guides and their results are uploaded to the cloud. Watch the video below to see it in action!

Details

As the technical lead on this project, I rigorously scoped out the project and kept everyone on track. I personally took on the networking since that was the biggest risk on this project. From experience, it usually become the largest headaches down the line if not done correctly. I’m talking about things like being impossible to debug, desynchronized, messy to hook up, and worst case scenario, completely redone.

A concern of mine was working simultaneously with my team and breaking things. Under our timeline, I needed my developers to immediately start on gameplay, but our networking was still incomplete. I wasn’t sure if new networking code would break their work since it overlays the systems they work on. Thankfully, the components we used from the SDK were well designed and completely modular (All architected by me 😉). My teammates never needed to interface with the network code and could just focus on creating interactions and procedures.

I believe a virtual classroom benefits from maximizing immersion and focusing on the connection between the trainer, student, and forklift. The greatest strength of virtual reality in this case is it cuts down on training costs and can be done remotely. Any friction I can remove from this process, makes the entire experience smoother and enjoyable, allowing for better training and knowledge retention.

There were many times I did QA testing and felt certain details caused unnecessary friction in the experience. Being true to life is not effective nor necessary to replicate in VR. I contemplated what real life processes were important to include, such as getting down against the ground to view a component, or performing unscrewing action several times for every bolt. I improved these by raising the forklift on a pedestal, and making the unscrewing action a singular animation instead.